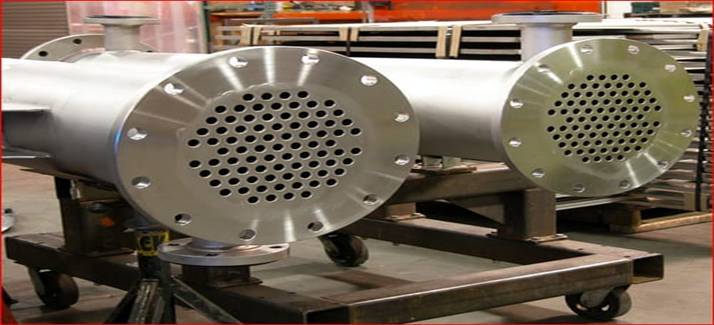

Heat Exchanger

Heat exchange is an important part of the fine chemicals production process and for manufacturing pharmaceuticals. Equipment has to operate under optimum sanitary conditions and in accordance with GMP. It needs to be compact and efficient, but easy to clean and maintain. LIMRA range of heat exchangers fulfills these requirements and more. As well as ensuring a reliable operation, our solutions aid heat recovery to make processes more economical.

-

Standard Design Features:

- Roller Expanded, Seamless Tubes; exchangers will have 316L seamless tubes, polished to 25Ra or better

- Surface Finish: LIMRA polishes the exterior of our exchangers and insulation jackets to 50Ra

- Pitched for Cleanability: exchangers are pitched to encourage gravity draining of both sides of the unit. The weep slots incorporated into the pass partitions help to facilitate draining of fluids. Our return pockets and weep slots are also fully radiused and polished to enhance cleanability and drainability. Due to surface tension in highly polished tubes, air or heat may be required to fully drain exchangers.